Company's products

You are here: Home > Company's products > PA66 engineering plasticsPA66 flame retardant cold grade

Product Details

Product Description Product Description | PA66 flame retardant cold grade |

Product grade | Injection Molding Grade |

Product appearance | Character / black / other colors / particles |

PA66's profile:

Polyamide resin, the English name for the polyamide, referred to as PA. Commonly known as nylon (Nylon)

PA66 (Polyamide 66 or nylon 66), compared with PA6, PA66 is more widely used in the automotive industry, the instrument shell and other needs of the impact resistance and high strength requirements of the product.

It is a generic term for polymers containing amide groups in macromolecule repeats. For the five largest engineering plastics in the largest output, the largest variety, the most versatile varieties.

(RIM) nylon, aromatic nylon, transparent nylon, high impact (super toughness) nylon, electroplated nylon, conductive nylon, resistance to the development of nylon, Burning nylon, nylon and other polymer blends and alloys, to meet the different special requirements, widely used as metal, wood and other traditional materials substitutes.

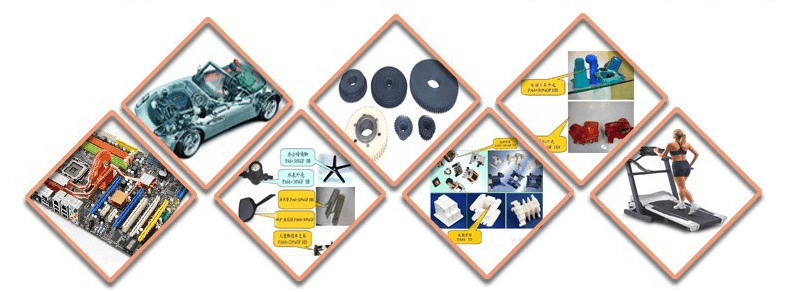

PA66 application:

Widely used in the manufacture of mechanical, automotive, chemical and electrical parts, such as gears, rollers, pulleys, rollers, impeller in the pump, fan blades, high pressure seals, seats, gaskets, bushings, , Support frame, inner bag and so on.

Custom plastic

(PA66); Fiberglass flame retardant heat stabilized nylon 66 (PA66); improved surface modification of nylon 66 (PA66) by improving the performance of nylon 66 (PA66) (PA66); flame retardant nylon 66 (PA66); flame retardant nylon 6 (PA6); carbon fiber grade nylon 66 (PA66); wear grade nylon 66 (PA66); ); Flame retardant organic filling grade nylon 66 (PA66); MOS2 filled nylon 66 (PA66) stainless steel fiber filled nylon 66 (PA66), etc., according to customer requirements for products by professional and technical engineers tailored for customers the most suitable The quality of engineering plastics products.