Company's products

You are here: Home > Company's products > PA66 engineering plasticsPA66 + MOS2 wear grade

Product Details

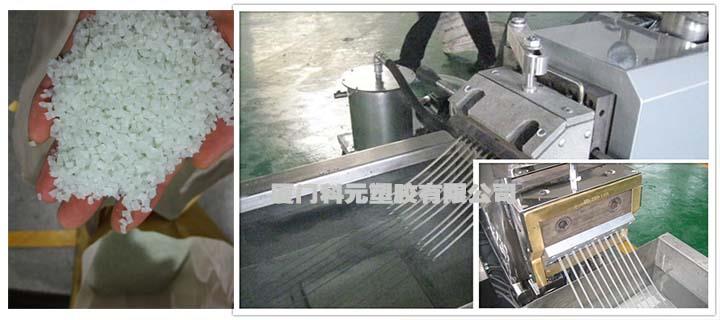

PA6 + Molybdenum Disulfide MOS2 Injection Molding Grade

Product Description Product Description | PA66 + MOS2 wear grade |

Product grade | Injection Molding Grade |

Product appearance | Character / black / other colors / particles |

MOS2 molybdenum disulfide introduction:

Black solid powder with metallic luster. Chemical formula MoS2, melting point 1185 ° C, density 4.80 g / cm 3 (14 ° C)  Mohs hardness of 1.0 ~ 1.5.1370 ℃ began to decompose, 1600 ℃ decomposition of metal molybdenum and sulfur. 315 ℃ in the air when heated to be oxidized, the temperature increases, the oxidation reaction to speed up. Molybdenum disulfide is insoluble in water and is only soluble in aqua regia and boiled concentrated H2SO4. It has also been known as "senior solid lubricants king". Molybdenum disulfide is a solid powder made from natural molybdenum concentrate powder after chemical purification to change the molecular structure. This product is slightly black with silver color, metallic luster, touch a creamy feeling, soluble in water. Products with good dispersion, non-bonding advantages, can be added in a variety of oils, the formation of non-adhesive colloidal state, can increase the grease lubrication and extreme pressure. Also applies to high temperature, high pressure, high speed and high load of mechanical working conditions, to extend equipment life. Molybdenum disulfide for the friction material is the main function of low temperature friction, high temperature when the friction, burning loss is small, volatile materials in the volatile; friction: by the supersonic airflow crushed from the processing of molybdenum disulfide particle size to 325 -2500 mesh, micro-particle hardness 1-1.5, friction coefficient of 0.05-0.1, so it can be used for friction material can play a role in friction; friction: molybdenum disulfide non-conductive, the presence of molybdenum disulfide, molybdenum trisulfide and three Molybdenum oxide copolymer. When the friction material due to friction and the temperature rose sharply, the copolymer of molybdenum trioxide particles with the temperature rise and expansion, played a role in the impact of anti-oxidation: molybdenum disulfide is a chemical synthesis of the comprehensive reaction, the PH value For 7-8, slightly alkaline. It is covered with the surface of the friction material, can protect other materials, to prevent them from being oxidized, in particular, so that other materials are not easy to fall off, sticking force increased; fineness: 325 mesh -2500 mesh; SIO2: 0; ; Density: 4.8-5.0 g / cm3; hardness: 1-1.5; loss of ignition: 18-22%; friction coefficient: 0.05-0.09.

Mohs hardness of 1.0 ~ 1.5.1370 ℃ began to decompose, 1600 ℃ decomposition of metal molybdenum and sulfur. 315 ℃ in the air when heated to be oxidized, the temperature increases, the oxidation reaction to speed up. Molybdenum disulfide is insoluble in water and is only soluble in aqua regia and boiled concentrated H2SO4. It has also been known as "senior solid lubricants king". Molybdenum disulfide is a solid powder made from natural molybdenum concentrate powder after chemical purification to change the molecular structure. This product is slightly black with silver color, metallic luster, touch a creamy feeling, soluble in water. Products with good dispersion, non-bonding advantages, can be added in a variety of oils, the formation of non-adhesive colloidal state, can increase the grease lubrication and extreme pressure. Also applies to high temperature, high pressure, high speed and high load of mechanical working conditions, to extend equipment life. Molybdenum disulfide for the friction material is the main function of low temperature friction, high temperature when the friction, burning loss is small, volatile materials in the volatile; friction: by the supersonic airflow crushed from the processing of molybdenum disulfide particle size to 325 -2500 mesh, micro-particle hardness 1-1.5, friction coefficient of 0.05-0.1, so it can be used for friction material can play a role in friction; friction: molybdenum disulfide non-conductive, the presence of molybdenum disulfide, molybdenum trisulfide and three Molybdenum oxide copolymer. When the friction material due to friction and the temperature rose sharply, the copolymer of molybdenum trioxide particles with the temperature rise and expansion, played a role in the impact of anti-oxidation: molybdenum disulfide is a chemical synthesis of the comprehensive reaction, the PH value For 7-8, slightly alkaline. It is covered with the surface of the friction material, can protect other materials, to prevent them from being oxidized, in particular, so that other materials are not easy to fall off, sticking force increased; fineness: 325 mesh -2500 mesh; SIO2: 0; ; Density: 4.8-5.0 g / cm3; hardness: 1-1.5; loss of ignition: 18-22%; friction coefficient: 0.05-0.09.

PA66 + MOS2 Features:

High wear resistance, high speed, high load, corrosion-resistant, non-conductive lead-gray powder, mainly from the role of lubrication, can also be used as a catalyst. Use industry: mainly used for aerospace industry, drill, brake pads, stainless steel, nonferrous metals, nylon 66 and 1010, plastic rubber, high-speed bearings and so on.