Company's products

You are here: Home > Company's products > PA6 engineering plasticsPA6 carbon fiber reinforced grade

Product Details

PA6 carbon fiber reinforced grade

Carbon fiber nylon, belonging to a conductive nylon

Is added in the nylon base material carbon fiber. The weight of the carbon fiber can determine the strength of the material as well as the electrical conductivity. Conventional addition of 30% carbon fiber, can reach 10 of 3-6 times, belonging to conductive products. In addition, in addition to carbon fiber can be conductive, but also can play a role in wear, strength will be greatly improved.

Glass fiber reinforced nylon production process there are two, one staple fiber, that is, short glass fiber and nylon after mixing extrusion granulation.

The other is long fiber method,

Fiberglass and nylon from different positions into the twin screw extruder:

Nylon and additives after adding a hopper,

Glass fiber from the glass fiber population through the screw rotation to its continuous into the screw.

Glass fiber reinforced nylon production process there are two, one staple fiber, that is, short glass fiber and nylon after mixing extrusion granulation.

The other is long fiber method,

Fiberglass and nylon from different positions into the twin screw extruder:

Nylon and additives after adding a hopper,

Glass fiber from the glass fiber population through the screw rotation to its continuous into the screw.

Glass fiber reinforced nylon production process there are two, one staple fiber, that is, short glass fiber and nylon after mixing extrusion granulation. The other is long fiber method, glass and nylon from different positions into the twin screw extruder: nylon and additives mixed after adding hopper, glass fiber from the glass fiber population through the screw rotation to its continuous into the screw.

In addition, the difference between carbon fiber and carbon black is that carbon fiber nylon density is lighter, many products in addition to the requirements of the material is impact resistance, but also the demand for density. Such as horse racing saddle, racing bike seat and so on. Carbon fiber nylon is the best choice.

Carbon fiber with a light weight, high tensile strength, wear resistance, corrosion resistance, creep resistance, conduction, heat transfer and other characteristics, compared with the glass fiber, high modulus 3 to 5 times, and thus a high rigidity and High strength nylon material excellent reinforcing material. Carbon fiber composites can be divided into long (continuous) fiber reinforced and short fiber reinforced two categories. The fiber length can range from 300 to 400 m to several millimeters. Over the past 10 years, a great deal of research has been devoted to improving the processing methods and properties of different types of carbon fiber composites. From the prepreg to the molding process, from the short fiber blending plastic injection processing to the laminate, in the carbon fiber composite materials and products produced a lot of successful experience. It is generally believed that long (continuous) fiber has high strength, high toughness of the superiority, chopped fiber with good processing characteristics. Therefore, long carbon fiber composite materials in the processing of the perfect molding process, short carbon fiber composite materials to further improve the mechanical properties of carbon fiber composite materials development direction.

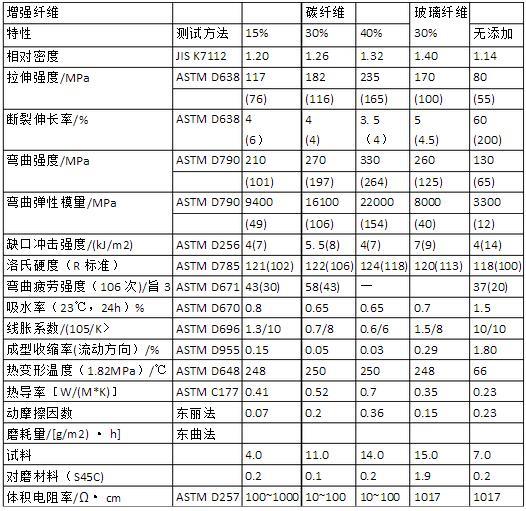

According to the carbon fiber length, surface treatment methods and the amount of different, can also be prepared with excellent overall performance, conductive properties of different conductive materials, such as antistatic materials, electromagnetic shielding materials, surface heating material, electrode materials. Carbon fiber reinforced nylon material developed rapidly in recent years, because nylon and carbon fiber are excellent performance materials in their respective fields, the composite material reflects the superiority of both, strength and rigidity than the unenhanced nylon is much higher, high temperature creep small , Thermal stability significantly improved, good dimensional accuracy, wear resistance, excellent damping, and glass fiber reinforced nylon compared to a better overall performance,

As shown in the table:

Note: () for the value of water absorption, no fiber when the moisture content of 2.5, containing fiber 15%, 30%, 40% moisture content were 1.9%, 1.6%, 1.5%; linear expansion coefficient Flow direction / vertical direction.

The mechanical properties of the composites are mainly related to the basic resin, the properties of the reinforcing fibers, the degree of bonding of the fibers and the resin interface, the extrusion process, the length and distribution of the reinforcing fibers.

Carbon fiber products are: carbon fiber nylon carbon fiber PA6 PA6 carbon fiber reinforced PA6 carbon fiber conductive PC plus carbon fiber PEEK carbon fiber nylon and carbon fiber nylon carbon fiber carbon fiber conductive carbon fiber conductive PA carbon fiber conductive PC carbon fiber conductive PPO carbon fiber conductive PPS carbon fiber conductive nylon carbon fiber resin carbon fiber reinforced carbon fiber reinforced PC carbon fiber Enhanced PPS Carbon Fiber Reinforced Nylon