Company's products

You are here: Home > Company's products> Case Classic Case > Other applicationsPBT injection molding materials

Product Details

Injection molding commonly used injection molding materials : PA6, PA66, ABS, PP, PVC, PC POM PBT and other engineering plastics.

Generally the basic requirements for injection mold materials have the following aspects.

1. Easy to process injection mold parts are made of metal materials, and some structural shape is still very complex, in order to shorten the production cycle, improve efficiency, require mold material easy to process into the drawings required by the shape and accuracy.

2. Good wear resistance Plastic surface gloss and precision and mold cavity surface wear resistance is directly related to, in particular, some plastic added to the glass fiber, inorganic fillers and some pigments, they and plastic Melt together in the runner, cavity in the high-speed flow, the friction on the cavity surface is very large, if the material is not wear, and soon will wear, so that the quality of plastic parts damage.

3. High corrosion resistance Many resins and additives on the cavity surface corrosion, this corrosion to the cavity surface metal corrosion, peeling, the surface condition deteriorated, the quality of plastic parts worse.Therefore, the best use of corrosion-resistant steel , Or on the cavity surface chrome, cymbals nickel treatment.

4. Good dimensional stability In the injection molding, the injection mold cavity temperature to reach more than 300 ℃. For this reason, the best choice of the appropriate tempering treatment of tool steel (heat treatment steel), otherwise it will cause the microstructure of the material Change, resulting in changes in mold size.

5. Heat treatment is small In order to improve the hardness and wear resistance, the mold is usually heat treatment, but this treatment should make its size change is very small.Therefore, it is best to use cutting hardened steel.

6. Good polishing performance Plastic parts usually require a good gloss and surface conditions, so the surface of the cavity surface roughness is very small, so that the cavity surface must be surface processing, such as polishing, grinding, etc. Therefore, the choice of steel Should not contain rough impurities and pores and so on.

Buy plastic injection materials on the election Xiamen Branch yuan !

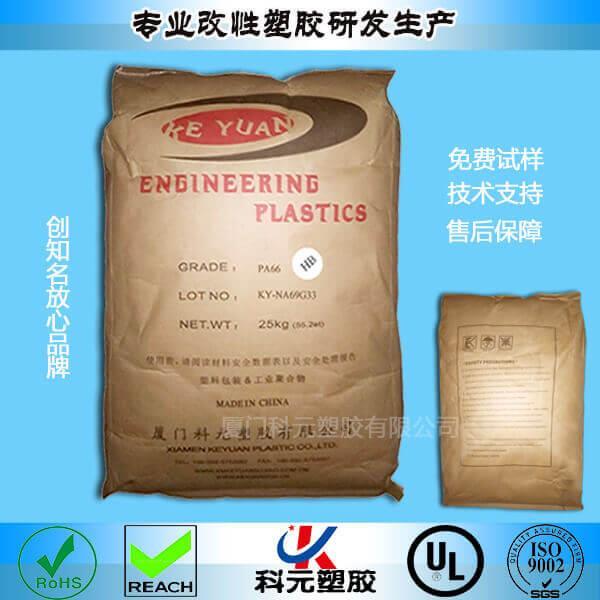

Xiamen Branch yuan Plastic Co., Ltd. professional R & D production and sales of modified engineering plastics integration company, the company specializing in the production of modified engineering plastics, according to product performance requirements for your tailor-made to meet their own materials, all products can meet the international material testing Standards, can provide SGS ; UL ; environmental protection and other related certification.

Other related information Click to enter the home page query or concerned about the WeChat public two public platform : xmkeyuan anytime, anywhere to grasp the industry-related information .

① common problems and solutions

②PDF physical document download

③ customer witness and experience