Company's products

You are here: Home > Company's products> Case Classic Case > Traffic and transportPa66 nylon

Product Details

Pa66 nylon

Product Description Product Description | Pa66 enhanced level |

Product grade | Injection Molding Grade |

Product appearance | Character / black / other colors / particles |

Introduction

PA66 plastic material for the translucent or opaque milky white package or with yellow granular crystalline polymer , with plasticity. Density (g / cm3) 1.10-1.14; Tensile strength (MPa) 60. 0-80.0 ; Rockwell hardness 118; melting point 252 ° C; brittle temperature -30 ° C; thermal decomposition temperature greater than 350 ° C; continuous heat resistance 80-120 ° C; impact strength (kJ / m2) 60-100; static bending strength (MPa) (0.00 cm) 1.83 × 1015; balanced water absorption of 2.5%; dielectric constant of 1.63; bending resistance of the elastic modulus (MPa) 2000 to 3000;

Chemical formula: [- NH (CH2) 6-NHCO (CH2) 4CO] n- can be acid, alkali, most inorganic salt solution, haloalkane, hydrocarbons, esters, ketones and other corrosion

PA66 in the polyamide material has a higher melting point in the product design, a PA66 shrinkage between 1% to 2%.

Now the market circulation with a lot of disposable nozzle through the modified, the same can achieve the physical properties of the original material, while the price is relatively cheaper than the raw materials a lot, so give the majority of merchants save a lot of cost.

PA66 for the five major engineering plastics in the largest yield, the largest variety, the most versatile varieties. Nylon in the main varieties are nylon 6 and nylon 66 , the absolute dominant position, nylon 6 is polycaprolactam, and nylon 66 is poly Diamine, nylon 66 , nylon 6 , nylon 9 , nylon 9 , nylon 13 , nylon 6 , nylon 6 , nylon 6 , , Nylon 9T and special nylon MXD6 (barrier resin), nylon modified varieties such as enhanced nylon, single-cast nylon ( MC nylon), reactive injection molding (RIM) nylon, aromatic nylon, transparent nylon, High impact (super tough) nylon, electroplated nylon, conductive nylon, flame retardant nylon, nylon and other polymer blends and alloys, to meet the different special requirements, widely used as metal, wood and other traditional materials substitutes.

Modified nylon is a kind of engineering plastics , is based on nylon raw materials as the base material to change its physical properties and the formation of granular products.The output of such products is based on the needs of some manufacturers and the need for modified production of.

Modified nylon generally includes:

characteristic

1 . Thermal properties: glass transition temperature ( T g ) and melting point ( T m ); high heat distortion temperature ( HDT ); long-term use of high temperature ( UL- 746B ); use temperature range; small thermal expansion coefficient .

2 . Mechanical properties: high strength, high mechanical modulus, low latency, strong wear resistance and fatigue resistance.

3 . Other: chemical resistance, electrical resistance, flame resistance, weather resistance, good dimensional stability.

The output of these products is based on the needs of some manufacturers and the need for modified production, modified nylon generally include: enhanced nylon, toughened nylon, wear-resistant nylon, halogen-free flame retardant nylon, conductive nylon, flame retardant nylon and many more.

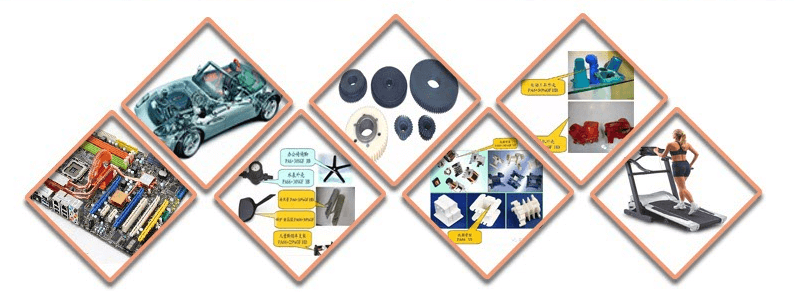

Modified nylon has a lot of features, therefore, in the automotive, electrical equipment, mechanical structure :, transport equipment, textiles, paper machinery and other aspects of widely used.

classification

Modified nylon is divided into: 1 , enhanced nylon 2 , flame retardant nylon 3 , transparent nylon 4 , wear nylon 5 , toughened nylon

New varieties

In the polyamide mixed with a variety of fibrous materials

Features: ⑴ high molecular weight ⑵ simple process, product shapes and diverse ⑶ large mechanical parts can be made ⑷ low water absorption

In the main chain in the introduction of benzene ring structure products high temperature, radiation resistance, corrosion resistance

Amorphous class

High transmittance, good dimensional stability

Process conditions

Drying: If the material is sealed before processing, then it is not necessary to dry. However, if the storage container is opened, it is recommended to dry in hot air at 85 ° C. If the humidity is greater than 0.2% , it is necessary to carry out 105 ℃ , 12 Hour of vacuum drying.

Melting temperature: 260 to 290 C. The glass additive product is 275 to 280 C. The melting temperature should be avoided above 300 C. Mold temperature: 80 ° C recommended . Mold temperature will affect the crystallinity, and crystallinity will affect the product's physical For thin-walled plastic parts, if the temperature of the mold below 40 ° C is used , the crystallinity of the part will change with time. In order to maintain the geometrical stability of the plastic parts, annealing is required. 750 ~ 1250bar , depending on material and product design Injection speed: high speed (slightly lower for reinforced material). Flow and gate: Due to the short settling time of PA66 , the location of the gate is very important. The diameter should not be less than 0.5t (where t is the thickness of the plastic part.) If the hot runner is used, the gate size should be smaller than using a conventional flow path because the hot runner can help prevent premature solidification of the material. The minimum diameter of the mouth should be 0.75mm . Typical use PA66 is more widely used in the automotive industry, the instrument shell and other products that require impact and high strength requirements. Transparent or opaque milky white crystalline polymer, Has a plasticity . 15g / cm3 . Melting point 252 ℃ . Brittle temperature -30 ℃ . Thermal decomposition temperature is greater than 350 ℃ . Continuous heat 80-120 ℃, balance water absorption 2 . 5% . Can acid, alkali, most inorganic salts of water, halogenated alkanes, hydrocarbons, esters, ketones and other corrosion .

Application areas

Widely used in machinery, instrumentation, automotive parts, electrical and electronic, railway, home appliances, communications, textile machinery, sports and leisure goods, tubing, fuel tanks and some precision engineering products. Electronic appliances: connectors, reel, timer, Circuit Breaker, Switch Seat Car: Cooling Fan, Gantry, Fuel Tank Cover, Air Gap, Water Tank Cover, Lamp Holder Industrial Parts: Chair Seat, Bicycle Drop Box, Ice Skate Base, Textile Shuttle, Pedal, Pulley.

Other related information Click to enter the home page query or concerned about the WeChat public two public platform : xmkeyuan anytime, anywhere to grasp the industry-related information.

A variety of modified plastic products ; general-purpose, enhanced, wear-resistant, high temperature, low warpage, high flow and plastic alloy for a variety of applications such as a series of products .

① common problems and solutions

②PDF physical document download

③ customer witness and experience

Xiamen Branch yuan Plastic Co., Ltd. professional R & D production and sales of modified engineering plastics integration company, the company specializing in the production of modified engineering plastics, according to product performance requirements for your tailor-made to meet their own materials, all products can meet the international material testing Standards, can provide SGS; UL; environmental protection and other related certification.