Company's products

You are here: Home > Company's products> Case Classic Case > Traffic and transportPBT engineering plastics wear grade / injection molding grade modified engineering plastics, used in steering wheel; combination switch; and other components production and processing of raw materials, free samples!

Product Details

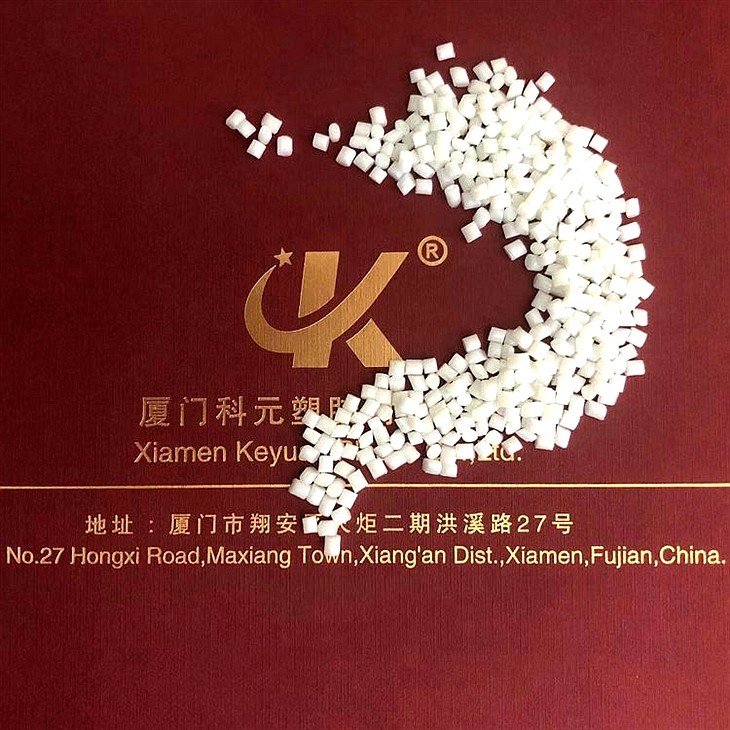

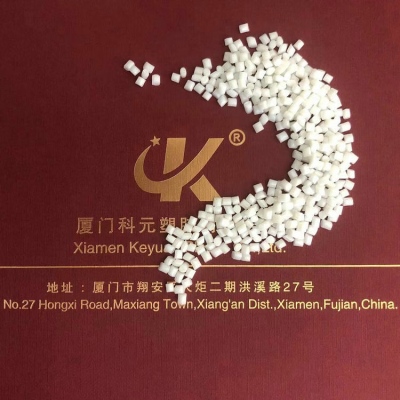

Specializing in the production of PBT engineering plastics wear grade / injection molding grade modified engineering plastics , used in steering wheel; combination switch; and other parts of raw materials, free samples! Section yuan plastic safer and more environmentally friendly!

Product Description Product Description | PBT enhancement level |

Product grade | Injection Molding Grade |

Product appearance | Character / black / other colors / particles |

Introduction:

Polybutyleneterephthalate , referred to as PBT PBTP or PTMT , which is a polycondensate of benzoic acid with 1,4 - butanediol , also known as polybutylene terephthalate , also known as polybutylene terephthalate . Can be produced by transesterification or direct lipidification by polycondensation, and the future development trend is the direct esterification production.PCOT and PET together are called thermoplastic polyester

advantage:

Modified PBT - PBT was milky white or light yellow, non - toxic, tasteless, the density of 1.31g / cm3, adding 30% glass fiber reinforced PBT density of 1.53 g / cm3.PBT has good impact toughness, glass fiber reinforced The mechanical properties of the glass fiber reinforced PBT decreased with the increase of the temperature, but the mechanical properties of the glass fiber reinforced PBT decreased with the increase of the temperature. At higher temperatures still maintain a high strength; at different temperatures, with excellent creep resistance, and almost no time with the change.PBT fatigue resistance than the enhanced PA, PC is good.Because PBT is crystalline Type polymer, so it has a significant melting point, usually 225 ℃, the processing temperature exceeds 270 ℃, the material began to break down, discoloration .PBT glass transition temperature is low, generally 30 ℃, crystallization faster; PBT heat distortion temperature 60 ℃, glass fiber reinforced significantly increased, adding 30% glass fiber reinforced PBT heat distortion temperature is 200-210 ℃, can be used at about 140 ℃ under the conditions of long-term use of PBT molecular structure symmetry and geometric regularity , it has very excellent electrical properties, high electrical resistivity and dielectric strength, PBT security work in high temperature and harsh environments, better than PA and other reinforced plastics.

1 , the mechanical properties of the stability of the tensile strength and tensile modulus and nylon similar; 2 , a small coefficient of friction from the self-lubricating; 3 , low water absorption; 4 , excellent electrical properties ; 5 , good dimensional stability; 6 , , Excellent oil resistance.

PBT process

PBT must be dried at a temperature of 110 to 120 ° C for about 3 hours before molding, and the molding temperature is 250 to 270 ° C. The mold temperature is controlled at 50 to 75 ° C. Since the material is cooled from the molten state, Solidification of the crystallization, so the cooling time is shorter; if the nozzle temperature control improper (low), the flow channel (outlet) easy to cool solidification, there will be clogging phenomenon if the cylinder temperature exceeds 275 ℃ or melt in the barrel stay More than 30 minutes, easy to cause decomposition of the material brittle. PBT injection need to use a larger nozzle into the glue, should not use the hot runner system, mold exhaust to be good, it is appropriate to " high speed, medium pressure, medium temperature " conditions molding processing, Material or glass fiber PBT outlet material should not be recycled, need to use PE or PP material in time to clean the material pipe, so as not to carbonization.

Xiamen Branch yuan Plastic Co., Ltd. professional research and development production and sales of modified engineering plastics integration company, the company's PBT engineering plastics are: to enhance PBT , toughening PBT , flame retardant PBT , low warping PBT and other modified products. Performance requirements for your tailored to meet their own materials, all products can meet international standards for testing materials, can provide SGS ; UL; environmental protection and other related certification.

use:

Used in electronic appliances: connectors, switch parts, household appliances, parts parts, small electric hood (heat resistance, flame retardant, electrical insulation, molding processing);

First, the use of automotive components :

1, the exterior parts: the main angle grille, the engine hood louvers and the like;

2, internal parts: the main stay endoscopy, the wiper support and the control valve system;

3, automobile electrical parts: ignition coil and the tube cutter variety of electrical connectors.

( PBT for the number of cars is not less than nylon, polycarbonate and POM, but with the emergence of low warp PBT , the future will be in the automotive parts to get more applications)

Second, the mechanical equipment: video tape recorder belt drive shaft, electronic computer hood, mercury lampshade, electric iron cover, baking machine parts and a large number of gears, cams, buttons, electronic table shell, camera parts (heat, Flame retardant requirements)

(Switch, motor case, fuse box, computer keyboard keys, etc.), automotive industry (radiator), household appliances (food processing blades, vacuum cleaner components, electric fans, hair dryer shell, coffee utensils, etc.), electrical components Grid windows, body panels, wheel covers, doors and windows components, etc.).

Hot search products:

PA6 PA66 modified modified modified modified PP modified ABS modified PBT PPS modified POM Alloy and other modified products.

Other related information Click to enter the home page query or concerned about the WeChat public two public platform : xmkeyuan anytime, anywhere to grasp the industry-related information .

① common problems and solutions

②PDF physical document download

③ customer witness and experience