Company's products

You are here: Home > Company's products > POM plasticPOM mineral fill enhancement level

Product Details

Product Description Product Description | POM Mineral Enhanced |

Product grade | Injection Molding Grade |

Product appearance | Character / black / other colors / customizable |

POM introduction:

Chinese name poly formaldehyde; race steel ~ Trane

English name Polyoxymethylene (Polyformaldehyde)

POM (polyoxymethylene resin) Definition: POM is a side chain, high density, high crystalline linear polymer. According to its molecular chain in the chemical structure of the different, can be divided into two kinds of paraformaldehyde and paraformaldehyde. The difference between the two is that the density, crystallinity and melting point of the homopolymer are high, but the thermal stability is poor, the processing temperature range is narrow (about 10 ℃), the stability of the acid and alkali is slightly lower; and the copolymer formaldehyde density, Melting point, the strength is low, but the thermal stability is good, easy to break down, processing temperature range (about 50 ℃), the acid and alkali stability is better. It is an engineering plastics with excellent overall performance. Has good physical, mechanical and chemical properties, especially with excellent abrasion resistance. Commonly known as steel or steel, for the third largest general plastic. Suitable for the production of wear-resistant wear-resistant parts, transmission parts, as well as chemical, instrumentation and other parts.

POM features:

Advantages: 1, with high mechanical strength and rigidity; 2, the fatigue strength; 3, environmental resistance, good resistance to organic solvents;

4, the resistance to repeated impact strong; 5, a wide range of temperature range (-40 ℃ ~ 120 ℃); 6, good electrical properties;

7, good recovery; 8, with their own lubrication, good wear resistance; 9, excellent size and stability.

Plastic modification is the production of large quantities of general-purpose resin by petrochemical enterprises through physical, chemical, mechanical methods to improve or increase its function, in the electrical, magnetic, light, heat, aging resistance, fire resistance, mechanical properties The use of special environmental conditions to achieve the function. Modified plastic is a wide area of plastic industry, covering a wide range of high technological content and creating huge economic benefits. The plastic modification technology - filling, blending and enhanced modification is in-depth almost all of the plastic products of raw materials and molding process. From the production of raw materials to a variety of specifications and varieties of modified plastic masterbatch, in order to reduce the cost of plastic products, improve its functionality, can not do without plastic modification technology. Mineral fill POM material performance in some areas to improve, improve, or its processing performance is improved, it is important to use the correct choice of modifiers and processing aids. According to the global health, safety, environmental protection and other requirements, the use of plastic additives, functional, performance, health and safety and environmental protection have put forward higher requirements, efficient, multi-functional, non-toxic, Agent.

Branch of the plastic Co., Ltd. modified POM varieties are: plus glass POM ball steel is not shrinking plus glass beads POM mineral enhanced POM material toughening POM plastic anti-UV POM wear-resistant friction POM material plus Teflon wear POM material containing silicone oil wear POM plus MOS2 wearable POM antistatic POM material conductive grade anti-static POM impact resistance elastic POM impact toughness POM food grade certification POM material high temperature POM material hydrolysis resistance corrosion resistance POM chemical resistance POM poly Formaldehyde insulation resistance arc POM cold and low temperature POM material modified POM plastic.

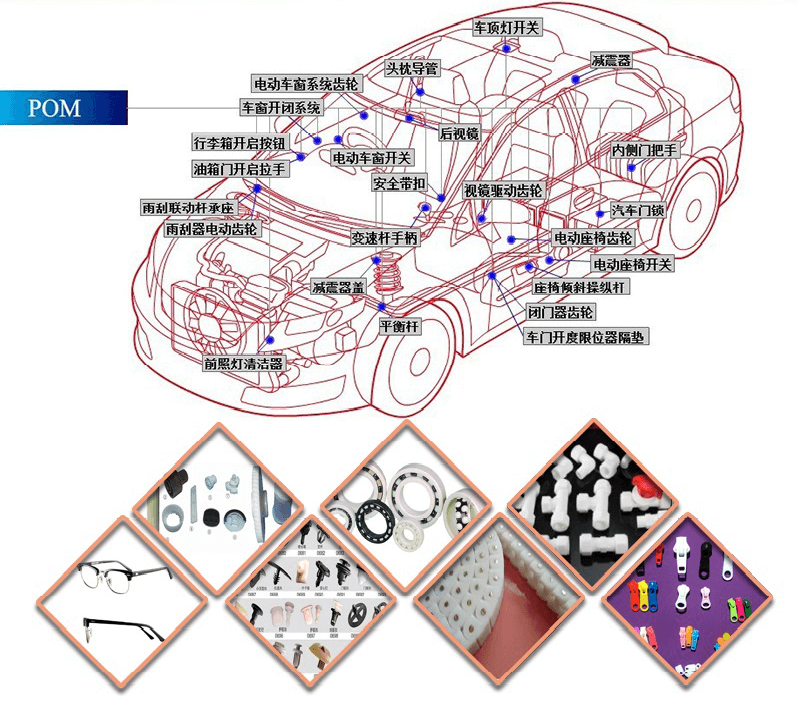

POM application: