Company's products

You are here: Home > Company's products > POM plasticPOM molybdenum disulfide filling grade

Product Details

POM molybdenum disulfide Mos2 filling grade

Product Description Product Description | POM molybdenum disulfide filling grade |

Product grade | Injection Molding Grade |

Product appearance | Character / black / other colors / customizable |

POM introduction:

Chinese name poly formaldehyde; race steel ~ Trane

English name Polyoxymethylene (Polyformaldehyde)

Molybdenum disulfide MOS2 is an important solid lubricant, especially for high temperature and high pressure. It also has a magnetic resistance, can be used as a linear photoconductor and display P-type or N-type conductivity of the semiconductor, with the role of rectification and transduction. Molybdenum disulfide can also be used as a catalyst for the dehydrogenation of complex hydrocarbons.

It is also known as ' Senior solid lubricants king'. Molybdenum disulfide is a solid powder made from natural molybdenum concentrate powder after chemical purification to change the molecular structure. This product is slightly black with silver color, metallic luster, touch a creamy feeling, do not dissolve in water. Products with good dispersion, non-bonding advantages, can be added in a variety of oils, the formation of non-adhesive colloidal state, can increase the grease lubrication and extreme pressure. Also applies to high temperature, high pressure, high speed and high load of mechanical working conditions, to extend equipment life.

POM features :

(1) POM can be dried before drying, preferably in the process of preheating (about 80 ℃), the stability of the product size is good.

(2) POM processing temperature is very narrow (0 ~ 215 ℃), stay in the barrel longer time or temperature exceeds 220 ℃ when it will break down, resulting in strong irritant formaldehyde gas.

( 3 ) POM material injection pressure to be larger (similar to the injection pressure), to reduce the pressure drop. Screw speed can not be too high, the residual amount is less;

( 4 ) POM product shrinkage is large, easy to produce shrinkage or deformation. POM than the heat, mold temperature is high (80 ~ 100 ℃), product stripping is very hot, need to prevent scalding fingers.

( 5 ) POM should be in the "medium pressure, medium speed, low material temperature, high mold temperature" under the conditions of molding processing, precision products need to use molding control mold temperature

( 6 ) with high mechanical strength and rigidity

(7) the highest fatigue strength

( 8 ) environmental resistance, good resistance to organic solvents

( 9 ) resistant to repeated impact , good electrical properties , good recovery , with their own lubrication, good wear resistance , excellent dimensional stability . POM application :

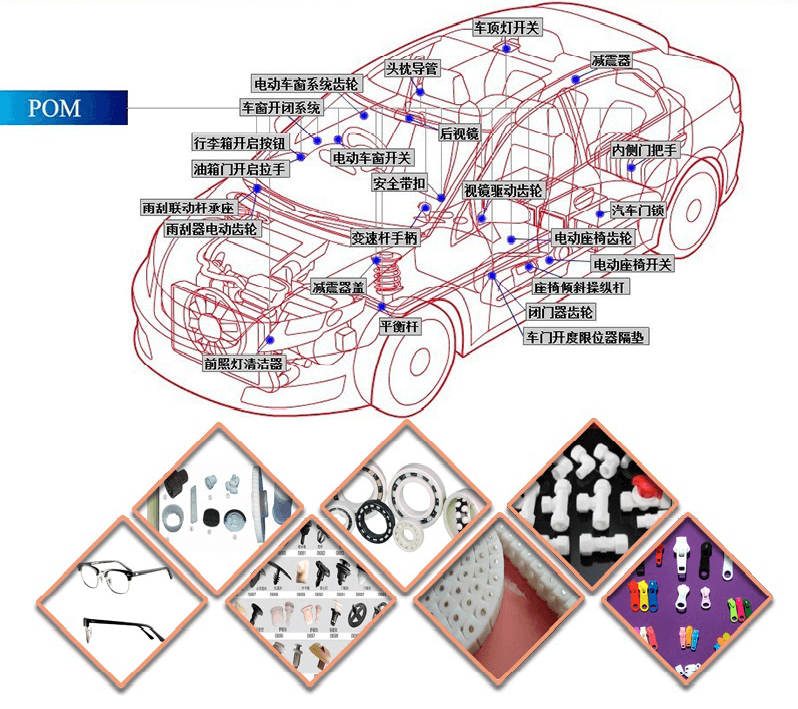

Can replace most of the non-ferrous metals, automobiles, machine tools, instrument parts, bearings, fasteners, gears, springs, pipes, conveyor belt accessories, electric kettle, pump shell, drain, faucet and so on.

The purpose of the modified POM is to improve the performance of the POM and to modify the POM. The POM is: POM; Wear-resistant POM; POM; Carbon-grade POM; Molybdenum disulfide Grade POM; conductive grade POM; organic filling grade POM; stainless steel fiber reinforced POM and so on. Specific products can be tailored according to product requirements for your product.