Industry knowledge

You are here: Home > Industry knowledgeContentHello, I am a PET, here's my resume! (Collection) manufacturer; manufacturers supply specializing in the modification, processing the custom; modified engineering plastics plastics

Want to know more friends in micro letter of concern to the public; xmkeyuan, stamp, blue tuned!

Want to know more friends in micro letter of concern to the public; xmkeyuan, stamp, blue tuned!

PBT is the General industrialization in a variety of the latest and the fastest, it's become the rising star of engineering plastics, first of all, is that it has excellent performance and good processing and outstanding price-performance ratio, therefore PBT plastic while industrial production only to 70, but the market soon, is now one of the five fastest-growing engineering plastics. This PBT from the introduction, development, processing, modification, application and frequently asked questions in six directions to you. Reply PBT view more related articles

A, PBT's profile

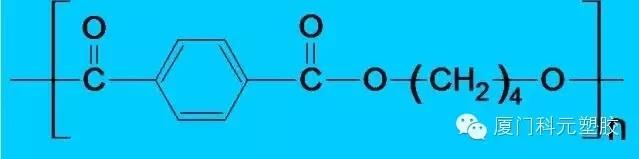

Polyethylene terephthalate glycol, English name of polybutylene terephthalate (PBT for short), belonging to the pet series, from 1.4-PBT Butanediol and Terephthalic acid or Terephthalic acid ester, poly-condensation, and mixing procedure and cream made from translucent to opaque, crystalline thermoplastic polyester resin.

Table 1 basic properties PBT

Chemical name: polyethylene terephthalate dimethyl ester |

Density: 1.31g/cm3

The glass transition temperature: 20 ℃

Tm:225℃

Molding shrinkage: 1.7 —2.3%

Water absorption: 0.34%

PBT and PET are similar in structure, different places were: ester of the repeating units of methylene-4 , this means that increase in flexible , rigid chain per cent decline , PBT molecular flexibility increased . Therefore, PBT stiffness , hardness , andTg and melting point than the PET to lower , higher toughness than PET , crystallization velocity faster than the PET, molding easier. More comparison with the PET, you can click on the blue links, viewing:→ Hello, I am a PET, here's my resume! (Collection)

Figure: molecular structure of PBT

Figure: molecular structure of PBT

Second, the history of PBT

1942 , Germany scientists P.Schlack, developed by

Zhihou , United States Celanese Corporation (now the Ticona) for industrial development and Celanex trade names listed

1970 , 30% glass fiber reinforced plastic market, trade name X-917, later changed to CELANEX

1971 , Eastman introduced glass fiber reinforced chain and enhanced products

That same year GE company , have developed similar products, not to strengthen, enhance, and three varieties of self-extinguishing

Subsequently , world-renowned manufacturers Germany BASF, and Bayer and the United States GE, and Ticona, Japan Toray and Mitsubishi Chemical, Taiwan new optical fiber, the Changchun man-made resins, plastics company has invested in the production ranks in South Asia, global manufacturers amounted to more than 30 companies

San, PBT molding process

PBT easy hydrolysis at high temperature, so drying before processing is very important. Usually melt temperature: 225 c —275 c, so the nozzle temperature 250 ° c, not reinforced PBT material for mold temperature 40—60 ℃, injection pressure medium speed as fast as possible (PBT crystallized quickly). Reply; PBT, view more related articles

Table 2 PBT molding conditions

Drying temperature (℃) |

110 ~120

Drying time (HR )

2 ~3

Mold temperature (℃)

50~75

Scrap quantity (mm)

2~6

Melt temperature (℃)

250~270

Back pressure (MPa)

5~10

Injection pressure (MPa )

100~140

Clamping force of about (ton/in2)

3~4

Injection speed

High speed

Return speed (RPM)

70~90

Screw type

Standard screw (straight-through nozzles)

Stop processing

Close the gate beer clear

Scrap reuse (%)

15~25

Note: fire-resistant PBT Need to use PE Gun, nozzle material not suitable for recycling.

Four, the modification of PBT

PBT has excellent performance, but single use thermal deformation at low temperature, flammability, mechanical, not prominent, especially product impact are not high and other shortcomings. PBT rarely used alone, most can be modified. Modification of PBT common methods:1, physical modifications; 2. flame retardant modification. 3. blending; 4.5, modified by chemical liquid crystal modification . For more specific information, you can click on the blue link → PBT three directions of modification —— physics/chain/blends

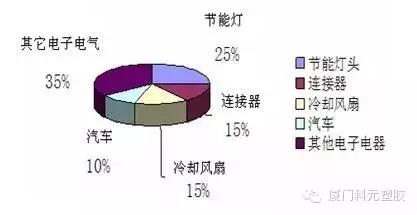

Map: PBT in the application of energy-saving lamp

Major producer of modified PBT

Manufacturers |

Major markets

Major industry

Taiwan Changchun

In South China, East China, North China and Northeast China

Automotive, electronics, home appliances, commercial appliances, lighting

Taiwan Shin

In South China, East China, North China and Northeast China

Automotive, electronics, home appliances, commercial appliances, lighting

Guangzhou kingfa

In South China, East China, North China and Northeast China

Automotive, electronics, home appliances, commercial appliances, lighting

Nantong blue

South/East

Electrical and electronics, home appliances, lighting

Nantong Orient

East China

Lighting, electrical

Five, PBT applications

PBT has modified a number of advantages: stable mechanical properties tensile strength and resistance to Zhang Mo, and nylon are similar small coefficient of friction with self-lubrication; low water absorption in electrical properties are excellent; good dimensional stability; drug resistance, oil resistance is excellent. So it is widely used in areas such as electronic appliances, automobile and industrial spare parts. → Article read PBT material industry

Table 3 modification of PBT engineering plastics applications

The field of home appliances

PBT plastic: thermoplastics, soft and difficult to deformation, high temperature (200 degrees), the surface is smooth (high crystallinity).

1.→ modification of PBT in irons on the 4 major advantages

Map: PBT applications in electric irons

Electrical and electronic fields

PBT+GF%, greatly enhanced strength and hardness, and flame retardant V0 levels can be achieved, and itself has good insulation, good gloss , so commonly used in the electrical and electronic fields. More specific electrical and electronic applications, you can click on the blue links:

Super-toughened PBT

1..→ Super-toughened PBT engineering plastics applications in the field of electronic connectors

Highlight environmentally friendly halogen-free flame retardant PBT (electronics)

2.→ a high gloss surface of non-halogen flame retardant PBT of composite materials in electrical and electronic applications

Low voltage electrical apparatus

3.→ Modifying PBT engineering plastics applications in the field of low voltage electrical apparatus

The automotive sector

Reinforced PBT according to the different needs, can be used for car interior and exterior materials, interior materials, high temperature resistance, low gloss, high weather resistance , such as outstanding performance, as exterior materials with high strength, high toughness and impact resistance, resistance to environmental conditions . For more details, you can click on the blue links and queries:→ PBT engineering plastics applications in the automotive sector

Run field

Currently PBT in the drawing area consists of stretch yarns and monofilament , single wire, wire brush-making and a wig. Filaments are mainly Advanced paint brush, toothbrush, brushes, makeup brush, carpet yarn . More specific details, you can click on the blue link to view:&rarr. What you don't know: these brushes are the basis of PBT resin production!

Six common problems, PBT plastic

Although, PBT has excellent of integrated can, as: can fast forming, and Crystal degrees high, and resistance waiting sex, and wear sex, and hot deformation temperature high, and electrical performance better, and mechanical performance excellent,, but also has anti-rushed toughness low, relative compared hard crisp, forming contraction rate big, resistance hydrolysis sex poor, especially by glass fiber enhanced Hou, products easy occurred Alice song, surface easy produced floating fiber. So here's to explain why PBT is the problem and answer of how to avoid these problems in the actual production process . Reply to “ PBT” for more related articles

Notch sensitivity, liquidity, warping, surface

1. modified PBT material injection six solutions

Warpage

2. solve non-halogen flame retardant glass fiber reinforced PBT warpage

Floating fiber issues

Fiberglass floating fiber products how to remove 3.PBT+15%?

Articles by aibang polymer exclusive arrangement

Reprints to share information, original all rights reserved.

下一条: No Information

Related Industry Knowledge

- I am the ABS, the scientific name: acrylonitrile-butadiene-styrene, here's my resume! Supply of modified plastics modified engineering plastics

- PA/ABS introduction to marriage--enhanced levels; filled plastic; flame retardant; modified processing injection materials nylon PA66; modified nylon and polyamide nylon; modified polyamide engineering plastics

- I am pp, PP called me, here's my resume! Pp; polypropylene fiber modification of polypropylene staple fibre manufacturer plastic

- I'm PE, PE called me, here's my resume! Reinforced grade/flame retardant modified engineering plastics manufacturers

- I am a Pom, POM called me, here's my resume (collection) engineering plastics modification of plastics

- I am a polycarbonate, everyone calls me PC, here's my resume and fill plastic flame retardant

- Car debris box shell mold design analysis (mold industry) enhanced level PA66 + GF30%