Industry knowledge

You are here: Home > Industry knowledgeContentI am a Pom, POM called me, here's my resume (collection) engineering plastics modification of plastics

Polyoxymethylene plastic people are on the public road; xmkeyuan, stamp, blue tuned!

Polyoxymethylene (POM) is a high performance engineering plastics in foreign “ killed steel ”, and “ ultra steel ” said. POM has a similar metal hardness, strength and rigidity, over a wide temperature and humidity range with good lubricity, good fatigue resistance, and flexibility, in addition, it has a good resistance to chemicals. POM, this article will profile, history, classification, modification, synthesis, processing, applications, eight ways to introduce main production enterprise. Reply to “ Pom ; for more related articles

A brief, Pom

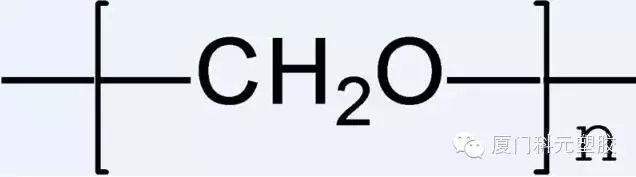

Pom, contains-CH2-O-of linear molecular chain link in the main chain polymers, scientific name polyethylene oxide methylene (polyoxymethylene, POM for short), is no side chains of high melting point, high density, crystalline thermoplastic polymer. It is following and a best performance of polyamide engineering plastic with high mechanical properties, such as strength, modulus, abrasion resistance, toughness and fatigue resistance, and creep resistance, also has excellent electrical insulating properties, solvent resistance and processability, is one of the five General engineering plastics.

Figure 1: structure of polyoxymethylene

Figure 1: structure of polyoxymethylene

POM main chain by — C—O—, and is supposed to be “ flexible ”, chain pronation is supposed to be easy, but due to the chemical structure that is regular and symmetrical, Intermolecular forces, crystallization, molecular motion and internal rotation of the chain becomes difficult, POM is a no side chains, thus piling up close, high density, linear polymer with high crystallinity.

Second, the history of the Pom

Herman · Staudinger, 1920 research on polymer POM's structure and aggregation process is found;

In 1952, another POM was synthesized by DuPont chemist, and in 1956 for its patented homopolymer;

United States Celanese Corporation in 1960 to manufacture a copolymer Pom POM;

Since then, Japan, Western Europe and other countries have also put into production.

2:POM Japan Po GH-25D

2:POM Japan Po GH-25D

Classification and difference of three, Pom

POM is mainly divided into: Pom (trioxane or formaldehyde polymer) and acetal copolymer (trioxane and small amounts of oxygen two rings of copolymer).

POM

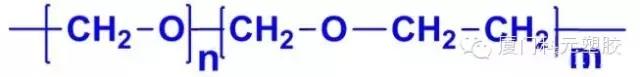

Figure 3: structure of polyoxymethylene

Acetal copolymer

Figure 4: the molecular structure of polyoxymethylene copolymer

From the structural point of view, Pom is made of pure-C-O-key continuous composition, and polyoxymethylene copolymer is distributed in several C-O-key-C-C-key, due to C-C-key-C-O-key stability good, POM copolymer thermal stability and chemical resistance and stability are good. Although there are some differences on the two kinds of structure of polyoxymethylene, polyoxymethylene copolymer chain — C— Very small proportion of C— keys (3% or 5%), so the two Pom performance is similar.

Table 1 Pom acetal copolymer performance comparison

Performance |

POM

Acetal copolymer

Density (g/cm3)

1.43

1.41

Crystallinity (%)

75-85

70-75

Melting point (℃)

175

165

Mechanical strength

High

Lower

Thermal stability

Less easy to resolve

Well, is not easy to decompose

Chemical stability

Slightly less acid and alkali stability

Good acid and alkali stability

Process temperature range

The narrow, about 10 ℃

Narrow width, about 50 ℃

POM in the process of forming a crystalline, generate larger crystals, when the material when subjected to shock, these larger crystals tend to form stress concentration points, causing material damage, POM notch sensitivity, notched impact strength, high mold shrinkage, product easy to produce internal stress, it is more difficult to close. This greatly limits the scope of POM, in some ways does not meet industry requirements. So in order to expand the application of POM, modification is needed to achieve this. For more information, you can click on the blue link Pom modification method and its application

Common methods of modification of POM are: a) the toughening modification; b) reinforced modified; c) wear modified; d) flame retardant modification; e) modified and so on. For more detailed information, you can click on the blue links: [Pom base] POM modification discussions;

Synthesis technology of five, POM

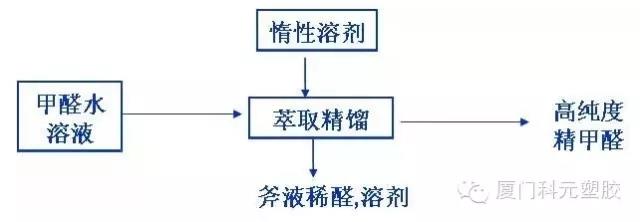

1. Monomer purification

Join PVA inert solvents dimethyl ether (PEGDME), formaldehyde and water azeotropes disappears, you can use the method of distillation, distillate of high purity formaldehyde.

Figure 5 Pom preparation process

2. Polymerization reaction

Acetal copolymer is also an ion polymerization, BF3 complexes as initiator, conducted in a twin-screw reactor, can achieve the desired polymer. POM end groups are active, and must be blocked, or it will automatically degrade.

Pom with acetic anhydride capped polyoxymethylene copolymer molecular weight regulator to join, generally end for methyl ether, hydroxy ethyl ether butyl ether, after blocking, blended with additives and granulation.

Processing technology of six, Pom

As with most thermoplastic, injection, extrusion, blow molding methods required for processing into various precision injection parts, sheets, rods, profiles, or hollow parts. For details of polyoxymethylene plastic injection molding process, you can click on the blue link: 35 injection molding DuPont POM dry PPT

Figure 6: injection molding process model

Seven, the application of POM

POM performance is excellent, especially its abrasion resistance, chemical resistance and fatigue resistance, and therefore access to a wide range of applications. Main application area of POM, able to produce carburetor parts, pipelines, pumps, power valves, bearings, universal joints bearings, gears, cranks, handles, handles, instrument panel, sleeve, shields, auto lift window unit and auto electrical switches, safety devices, etc.

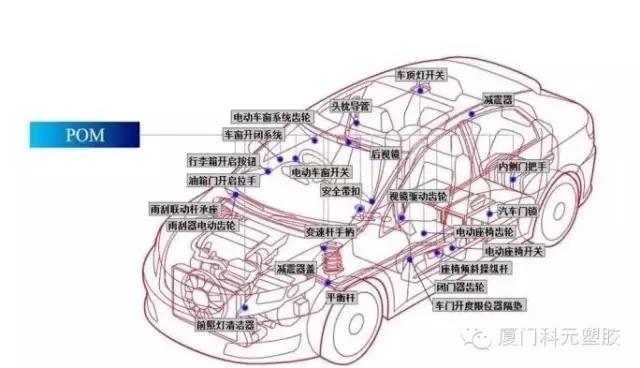

1. the automotive sector

Application of POM wear-resistant materials in the automobile industry

Figure 7:POM in automotive application

2. machinery manufacturing

Suitable for gears, chains, drive shafts, bearings, valve stem nut, impeller, rollers, cam and a variety of mechanical parts, electric tool shell handle and switch technology posted: POM in the solution of the gear (part one)

8:POM example application in mechanical manufacturing industry

3. the electrical and Instrumentation industry

Technology tell you use the mouse, keyboard, POM

4. the water heating building material industry

Manufacturing faucet spray nozzle, door and window parts, pulleys, etc.

5. light industry

Activities mainly used in ball-point pen and replacement parts, pressure nozzles, disposable lighters, gas valves, zipper, cookie molds, and so on.

6. the weapons and the military

Making mortar ammunition, rifle fire, tanks and armored vehicles of various mechanical components, instrumentation components and rotating, reciprocating wear-resistant seals and so on.

Previous: I am a polycarbonate, everyone calls me PC, here's my resume and fill plastic flame retardant

Related Industry Knowledge

- Hello, I am a PET, here's my resume! (Collection) manufacturer; manufacturers supply specializing in the modification, processing the custom; modified engineering plastics plastics

- I am the ABS, the scientific name: acrylonitrile-butadiene-styrene, here's my resume! Supply of modified plastics modified engineering plastics

- PA/ABS introduction to marriage--enhanced levels; filled plastic; flame retardant; modified processing injection materials nylon PA66; modified nylon and polyamide nylon; modified polyamide engineering plastics

- I am pp, PP called me, here's my resume! Pp; polypropylene fiber modification of polypropylene staple fibre manufacturer plastic

- I'm PE, PE called me, here's my resume! Reinforced grade/flame retardant modified engineering plastics manufacturers

- I am a polycarbonate, everyone calls me PC, here's my resume and fill plastic flame retardant

- Car debris box shell mold design analysis (mold industry) enhanced level PA66 + GF30%