Industry knowledge

You are here: Home > Industry knowledgeContentI am a polycarbonate, everyone calls me PC, here's my resume and fill plastic flame retardant

I am a polycarbonate, everyone calls me PC, here's my resume (specializing in the production of modified plastics)

Friends of polycarbonate micro letter of concern to the public; Xmkeyuan, stamp, blue tuned!

A, introduction

Polycarbonate (PC for short) is a molecular chain containing carbonate of polymers, transparent colorless or slightly yellow solid toughening, transparency after the PMMA and PS, light transmission rate of up to 89%, odorless, nontoxic, good coloring can be made into all kinds of colorful products.

Table 1 Basic attributes of polycarbonate

Chinese name |

Chemical formula

Polycarbonate

2,2'--bis (4--hydroxyphenyl) propane polycarbonate

English name

CSA

Polycarbonate

25037-45-0

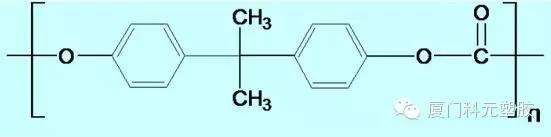

No special instructions, commonly referred to as the polycarbonate are all examples of Bisphenol a polycarbonate and modified varieties, following is the structure of Bisphenol a polycarbonate.

Map: 2,2'-bis (4--hydroxyphenyl) propane polycarbonate

Groups in the main chain effect on PC

1. phenylene base : large rigid groups limits the build-up of internal rotation of the chain segments;

2. ester : strong polar groups, providing greater Intermolecular force makes the molecules bound to each other, weakening flexible molecular chains;

PHENYLENE based and ester groups determine the PC is the property of rigid macromolecules. Therefore, the polymer glass transition temperature and melt at a higher temperature, higher melt viscosity, molecular forces difficult to slip under, strong resistance to deformation, high strength, solvent resistance and water resistance.

Second, history

1953: Bayer's first polycarbonate (PC).

1958: Bayer to melt Transesterification PC scale of industrial production.

1960: the United States GM semi-industrialized production

In 1958, started developing in 1965, industrial plant

After the 80 's, PC demand grew rapidly, 80 's growth close to 13%, 90 to keep its revenues

Three, classification

According to the different-R-groups, polycarbonate can be divided into aliphatic, alicyclic, aromatic and aliphatic-aromatic types. No clear case, commonly referred to as polycarbonate is the modification of Bisphenol a polycarbonate and its varieties.

According to the purpose, polycarbonate can be divided into static-free PC, conductive PC, plus fiber fire PC, UV resistant PC, food-grade PC, PC chemical resistance.

Figure 2: food-grade PC particles

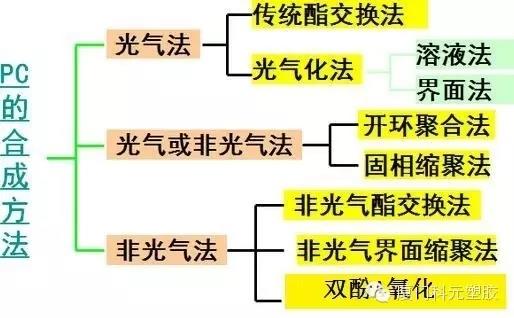

Four, synthesis process

Synthetic method of 3:PC

1. transesterification

In the alkaline catalyst, high temperature and high vacuum condition, Bisphenol a and diphenyl carbonate by Transesterification, removal of phenol, condensation into a polycarbonate. More specific details, you can click on the blue link to see: a comprehensive analysis of Polycarbonate-polycarbonate (PC)

2. phosgene method

Turn the Bisphenol a sodium salt, Bisphenol a sodium salt of the NaOH solution to in order to pass into phosgene dichloromethane for another phase, Interfacial polycondensation at normal temperature and pressure. Synthesis on internal PC material, you can click on the blue links to:→ progress of synthesis technology of the new PC in China break the foreign monopoly

Five, molding technology and injection defects analysis

1. forming process

PC plastic injection molding, extrusion, molding, blow molding, thermoforming, printing, adhesive, coating and machining , injection is the most important processing methods. Before forming must be dry, moisture content should be less than 0.02%, and trace moisture in high temperature processing will make the products have a whitish color, silver and bubbles, PC in room temperature with considerable force high elastic deformation capacity.

Table 2 Polycarbonate molding

Forming process |

Application

Injection molding

Used in the manufacture of sophisticated, high impact, small-scale products

Extrusion molding

PC Board, tubes and rods profiles and films

Blow molding

Hot cups, containers and other hollow articles

2. common injection molding defect analysis

PC is a relatively hard machining of plastics. Therefore, in the molding process is often discolored, yellow stripes, black, bubbles, cold spots, flow marks and other defects.

1) stress

(A) PC to eliminate internal stress cracking solution

(B) stress cracking of PC product solutions

(C) knowing these eight tips can help you reduce PC plastic stress

2) projective and black

(A) Mitsubishi color of transparent PC products be transparent black what?

(B) crystal clear PC molding there are projective solutions

Figure 4:PC injection molding products have projective case

3) surface from the skin

"Injection" PC without glass fiber surface is why?

5:PC no fibers from the skin

4) other issues

(A) master out of PC material injection molding problem summary (dry, Super practical! )

(B) PC-polycarbonate injection defects analysis and solutions

Six, PC modification direction and major producers

1. Why do PC modification?

Improved stress crack, illiquid

2. modification of PC have?

Toughened, reinforced flame retardant and alloying, more details on PC modification, you can click on the blue links to see:

(1) common class 4 modified modification of polycarbonate material (PC)

(2) from PC/ABS, ABS patent statistics said: people only modified plastics industry Commission River

3. modified varieties are there?

Table 3 PC modification of common varieties

Type |

Goal

Can improve the performance of flexural modulus, thermal, electroplating

Improve drug resistance, solvent resistance

Join plexiglass can improve the appearance of Pearl color

Improved toughness, surface finish

Improved water resistance, aging resistance, weatherability, and LDPE effect

Reinforced modified to improve mechanical strength

4. the main producers

Major PC producers are: Saudi basic industries Corporation, Bayer AG, Japan's Mitsubishi, LG chemical, light, Taiwan Chi Mei, Korea Samsung, jiaxing people, Singapore Teijin, Dow, Samsung's first hair weave, Russia Kazan, Thailand Mitsubishi, Ningbo Zhejiang Gale chemical. For more information, you can click on the blue link, the query:

Ningbo Zhejiang Gale chemical

1) good news: the first million tons of polycarbonate device production

2) SABIC SABIC PC resin, for example, master grade classification, nomenclature and application

3) Bayer

(A) "Favorites" Germany Bayer MAKROLON (PC) grades and applications

(B) Bayer Apec is a special type of polycarbonate

Six, the application

1. motor vehicles (good impact resistance, resistance to heat distortion properties, and good weather resistance, high hardness)

Applicable to the production of parts for cars and light trucks. Uses mainly focused on lighting systems, instrument panels, heating plate, defrost, as well as PC-metal bumper.

A) door handles: door handles in the Audi, Volkswagen bus selection plating grade PC/ABS why?

Figure 6:PC/ABS electroplating door handles (figure from Kumho rili)

2. electronics (good electrical insulation, flame resistance, dimensional stability)

Mainly used in the overloaded plugs and wall Board, connector, electronic products, Terminal binding posts, and so on.

A) 3C plastics industry on how tall access 3C electronic products? PC polycarbonate, for example

B) mobile phone shell application of halogen-free flame retardant PC/ABS in the cell phone case

Figure 7: mobile phone shell of polycarbonate (Meizu)

3. Optics (high transmittance, high refractive index, high impact resistance, good dimensional stability and easy processing)

The main field of application: optical, lenses, lighting, and other

"Video" from PC particles into the finished CD, full automation of production

Figure 8:PC in camera lenses

4. building (high penetration, impact-resistant, temperature-resistant, resistant to UV, dimensional stability)

Apply to :PC Board.

9:PC sheet for building materials

5. packaging

PC in the packaging sector is mainly made of 20L water bottle. Due to the light weight, impact resistance and good transparency, washed with hot water and caustic treatment without distortion and transparency, except a few upscale markets, PC bottles have replaced glass bottles.

10:PC bottle

6. medical devices

PC or its modified varieties with good toughness and rigidity, and resistance to heat, radiation, medical field of high temperature, high-pressure sterilization and subjected to high-energy radiation processing requirements, mainly for the manufacture of artificial dialysis equipment, blood collection devices, high pressure syringe, surgical masks and other necessary in transparent, intuitive operation and required repeated under the conditions in sterilized medical devices.

11:PC used in syringe

Articles edited by aibang polymer finish

Related Industry Knowledge

- Hello, I am a PET, here's my resume! (Collection) manufacturer; manufacturers supply specializing in the modification, processing the custom; modified engineering plastics plastics

- I am the ABS, the scientific name: acrylonitrile-butadiene-styrene, here's my resume! Supply of modified plastics modified engineering plastics

- PA/ABS introduction to marriage--enhanced levels; filled plastic; flame retardant; modified processing injection materials nylon PA66; modified nylon and polyamide nylon; modified polyamide engineering plastics

- I am pp, PP called me, here's my resume! Pp; polypropylene fiber modification of polypropylene staple fibre manufacturer plastic

- I'm PE, PE called me, here's my resume! Reinforced grade/flame retardant modified engineering plastics manufacturers

- I am a Pom, POM called me, here's my resume (collection) engineering plastics modification of plastics

- Car debris box shell mold design analysis (mold industry) enhanced level PA66 + GF30%