Industry knowledge

You are here: Home > Industry knowledgeContentPA/ABS introduction to marriage--enhanced levels; filled plastic; flame retardant; modified processing injection materials nylon PA66; modified nylon and polyamide nylon; modified polyamide engineering plastics

Polyamide (PA) due to its excellent mechanical strength, abrasion resistance, lubricity and corrosion resistance, has developed into one of the most important engineering plastics products. But its water absorption rate, poor dimensional stability and low temperature impact poor and dry, which greatly limited its application in certain areas.

ABS and PA were modified to be both both merits of PA/ABS alloy, obtained at the same time both of them do not have unique advantages, such as:

1. has a unique Matt effect, which is not available in other materials

2. no less easy to heat.

3. has a low density, which can effectively reduce costs.

4. excellent workability.

Of course, in addition to the advantages listed above, PA/ABS alloys have more advantages, such as wear resistance, chemical resistance and vibration damping. It is because it has so many advantages, PA/ABS materials from everyday glasses, stationary power tools, and so on.

Due to the PA and ABS of solubility parameter, polarity, Crystal has great difference, PA/ABS through simple mechanical blending material interface bonding strength between low and poor mechanical properties, have no practical value. Therefore, how to improve the PA and ABS compatibility is key to development of PA/ABS alloy.

Jia Yi Rong TM CMG-7000 is a developed specifically for PA/ABS alloy compatible agent, to provide excellent coupling solution. Through effective role in chemical bonding between the interfaces, enhanced Interfacial adhesion, maximum extent to enhance the mechanical properties and hydrolytic stability of composites.

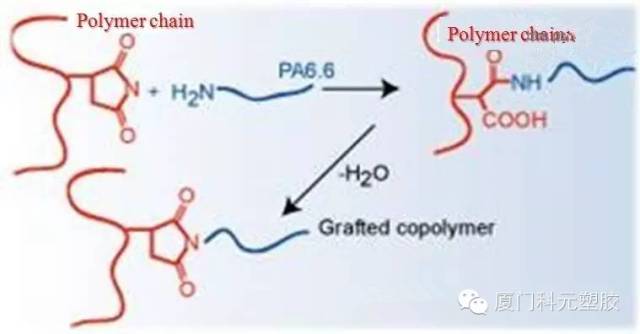

CMG7000 in PA/ABS alloy materials compatibility mechanism diagram

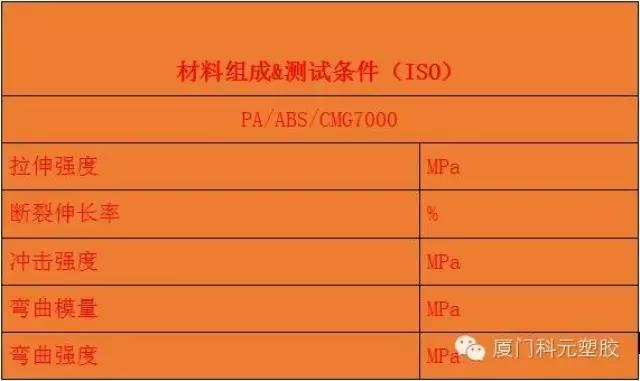

CMG7000 improved impact strength of PA/ABS alloy

Extrusion temperature: 220-250 c; injection temperature: 240-260 c; mold temperature: 60-80 c

The chart shows that, after adding CMG7000, PA/ABS alloys the elongation increased 5 times, impact strength increased 7 times.

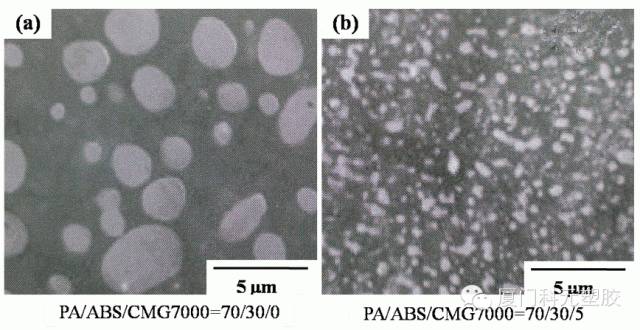

Add CMG7000, greatly reduce the diameter of dispersed ABS, numbers have increased markedly, absorb more energy when impacted, manifested as increased toughness, and I owe it all to the infiltration function of CMG7000 on the interface

PA/ABS alloy by SEM photographs

The original removal of polymers Forum, original all rights reserved! Reprints to share knowledge-sharing fun,

The daily highlights, Subscribe now!

For a common goal and hope: sharing knowledge, creating value! Welcome to our public service number: (ID:xmkeyuan)

Related Industry Knowledge

- Hello, I am a PET, here's my resume! (Collection) manufacturer; manufacturers supply specializing in the modification, processing the custom; modified engineering plastics plastics

- I am the ABS, the scientific name: acrylonitrile-butadiene-styrene, here's my resume! Supply of modified plastics modified engineering plastics

- I am pp, PP called me, here's my resume! Pp; polypropylene fiber modification of polypropylene staple fibre manufacturer plastic

- I'm PE, PE called me, here's my resume! Reinforced grade/flame retardant modified engineering plastics manufacturers

- I am a Pom, POM called me, here's my resume (collection) engineering plastics modification of plastics

- I am a polycarbonate, everyone calls me PC, here's my resume and fill plastic flame retardant

- Car debris box shell mold design analysis (mold industry) enhanced level PA66 + GF30%