Industry knowledge

You are here: Home > Industry knowledgeContentI am the ABS, the scientific name: acrylonitrile-butadiene-styrene, here's my resume! Supply of modified plastics modified engineering plastics

Professional plastics ABS who are concerned about Micro letter public; xmkeyuan, stamp, blue tuned!

This article is general plastic last post, written in front of four common plastics: PE, PP, PVC, PS. If you like it, make will continue to write about introduction to engineering plastics and specialty plastics. This article, from ABS introduction, classification, development, process, alloy, and some common defects in seven areas to introduce.

A, ABS profile

My name is ABS, scientific name: acrylonitrile-butadiene-styrene, English name: Acrylonitrile Butadiene Styrene. Normal to light yellow or milky white grain non-crystalline resin, fat little more than water:1.02-1.08g/cm3. Production is currently the largest and one of the most widely used polymers. I am PB, PAN, and the combination of PS and, therefore, both tough and hard and rigid balance characteristics (mechanical properties).

Table 1:ABS properties

Chinese name |

ABS 塑料

Foreign language names

Acrylonitrile Butadiene Styrene plastic

Chemical name

Acrylonitrile-butadiene-styrene plastic

Product features

Impact resistance, heat resistance, low temperature resistance

The scope of

Machinery, automobiles, electronic appliances

CAS 编号

9003-56-9

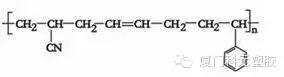

Photo: ABS formula, the meaning of the letters

A, representative propylene nitrile : propylene nitrile provides hardness, and heat sex, and acid alkali salt , chemical corrosion of nature; and d II en copolymer can business have NBR , its has good of resistance oil sex, Hardy sex, wear sex, and electric insulation performance, and in most chemical solvent, Sun and hot role Xia, performance compared stable.

NBR acrylonitrile content (%) include 42~46, 36~41, 31~35, 25~30, 18~24 and other five. More acrylonitrile content , resistance to oil the better, but cold fall .

B for butadiene : for ABS resins to provide low-temperature ductility and impact resistance, electrical properties , butadiene will decrease too much resin hardness, gloss and liquidity ; improve the styrene content can increase strength , elongation decreased adhesion variation; styrene content 50%~70% of butadiene-styrene copolymer resin, but pan said high-styrene rubber;

And styrene, styrene-butadiene rubber , styrene-butadiene rubber and includes:k-resin, SBS and SBR , with very good wear resistance, heat resistance, aging resistance.

K-resin (butadiene-styrene transparent impact resin ): anionic polymerization of a block copolymer synthesis of technology, an amorphous polymers, high transparency, high gloss, impact resistance, good processability;

SBS (Thermoplastic Elastomer):, a combination of plastic and rubber properties, with excellent electrical properties of tensile strength, elasticity, and permanent deformation, Flex and good compression, and surface friction.

SBR: divided according to production methods, styrene-butadiene rubber emulsion polymerization, solution polymerization styrene-butadiene rubber and the powdered styrene-butadiene rubber

1) polymerization of butadiene-styrene rubber : with wear-resisting, cold and lower heat build-up, shrinkage , color, less ash, high purity and curing speed advantages, and have small rolling resistance and wet skid resistance and wear resistance performance advantages;

2) emulsion polymerized styrene-butadiene rubber : processing performance , vulcanized rubber abrasion resistance , tensile strength, tear strength and resistance to aging well;

3) PSBR (powdered styrene-butadiene rubber): designed for modified asphalt production of powdered styrene-butadiene rubber, in addition to styrene-butadiene rubber significantly improved low temperature performance characteristics, powdered styrene-butadiene rubber or significantly improving the high temperature performance of asphalt ;

S for styrene : ABS resin provides hardness , process flow and surface Finish ;

With acrylonitrile copolymers, is AS resin , AS resin is a hard, transparent material. Styrene content more and more hard, transparent and easy to process AS resin; acrylonitrile is high (AS) better chemical and thermal stability.

If100% styrene , polystyrene , another common plastics. PS has a high degree of transparency, light transmission rate of up to 90% per cent, good electrical insulating properties, easy to be colored, processing and good liquidity, good rigidity and good chemical resistance.

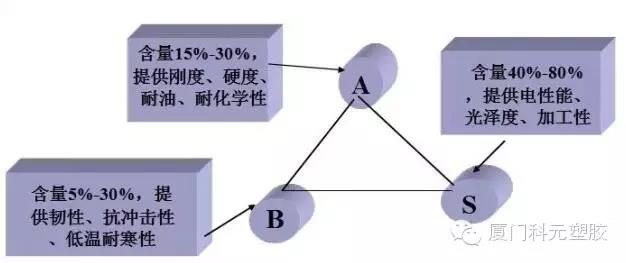

Is ABS have different properties of each component, so when ABS (acrylonitrile-butadiene-styrene) PAN and the PB and the PS unified when both tough, hard, just balanced by excellent mechanical and chemical properties. Composing content performance with different combinations in different ways, showing different ABS.

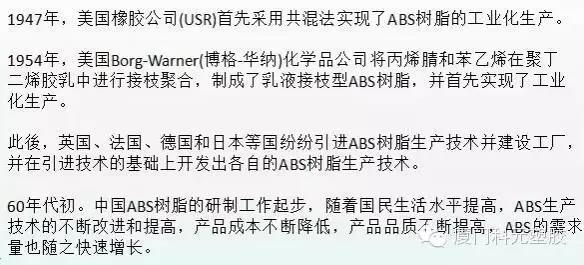

Second, history

Third, the ABS classification

Third, the ABS classification

Because I am a combination. And widely used, therefore, generally in accordance with my ability to describe me (classification). Such as: General (including resistance level) level, transparent, heat-resistant, flame retardant, plating grade, structural foam, and modified ABS and so on. For more information, you can click on the blue links, viewing:

&Amp;rarr; master ABS resin, you must see this!

→ Classification and application of ABS and ASA

Flame retardant ABS:→ I really don't know, flame retardant ABS play an important in the field of fire safety in public places!

Photo: ABS material particles

Photo: ABS material particles

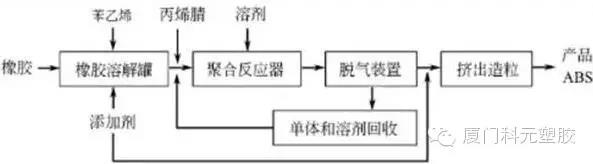

Four,ABS production technology

For me the origin of this is a long story. At present, the main emulsion polymerization and bulk .

Emulsion polymerization : The method is the polymerization of styrene with acrylonitrile AS, and then in a State of emulsion polymerization of butadiene into the ABS, this process AIDS remains more, yellow color, most products are for sale in the market this production (LG, CMO, Jilin Chemical, BASF, etc).

Bulk: continuous body ABS production technology including Sol, polymerization, polymerization, devolatilization and granulation 5 steps. Technology advantages:

1. the continuous production, the process is simple

2. less equipment, low investment, easy

3. less waste, less pollution, energy-saving and environmental protection

4. switch products

Current United States DOW and Sinopec Shanghai gaoqiao is using this technology. Emulsion polymerization products, bulk product color is white, but poor gloss; a wide temperature range.

Photo: ABS bulk polymerization process

Photo: ABS bulk polymerization process

Major world ABS resin manufacturers

China Taiwan Chi Mei, Korea LG group, Formosa Plastics Group, Germany BASF, and Ineos, and Toray Industries, and Cheil, Sabic, China Petroleum, Styron and others.

Table 2:2014 major ABS business

Group name |

Provinces

Enterprise name

Capacity

China petrochemical

Shanghai

Gaoqiao branch

20

China Petroleum

Jilin

Jilin petrochemical company

58

In Gansu province

Lanzhou petrochemical company

2

Other enterprises

Heilongjiang

Daqing petrochemical company

10.5

Jiangsu

Zhenjiang Chi Mei chemicals

75

Jiangsu

Chang Hu (Changzhou) chemicals

7

Zhejiang

Ningbo LG yongxing chemical

64.3

Zhejiang

Plastic (Ningbo)

45

Guangdong

CNOOC, LG chemical

15

Liaoning

Panjing shuangxing engineering plastics

19

Tianjin

Tianjin dagu chemical industry

40

Shanghai

Shanghai huayi

3.8

Other

359.6

Five, ABS alloy

It is because, I am a combination. Therefore, the easy compatibility with other races, so I'm usually with other plastics, get a new plastic alloys modified, thereby greatly improving my performance. Common ABS alloys are ABS/PC, and ABS/PA, and ABS/PBT, and ABS/PVC , and so on. There is also ABS/PSU, and ABS/EVA, and ABS/PVC/PET, and ABS/EPDM, and ABS/CPE, and ABS/PU alloys. For more information, you can click on the blue link to view:

Introduction of →PA/ABS alloy

&Amp;rarr; PC/ABS alloy usually say, exactly how much?

&Amp;rarr; introduction of polycarbonate-why so many PC/ABS alloys on the market? TPE package PC/ABS should pay attention to what?

Figure: application of ABS automobiles

Figure: application of ABS automobiles

Six, the application of ABS

With such a comprehensive ( impact resistance, high stiffness, oil resistance, low temperature resistance, chemical resistance and electrical properties, as well as easier processing, low price ) I must be an integral component of this world, so in the electronic and electrical, instrumentation, automotive, construction and industrial areas, I am everywhere.

Application of table 3:ABS

Automobile industry |

Office machines

Household appliances

Other

Instrument panel, radiator grille, mirror frames, ornaments

Telephone, memories shell casing

Fax machine, stereo, VCD

Packaging, sports and entertainment supplies

Licence plate, air conditioning air outlet

Computers, fax machines, copiers

Vacuum cleaners, washing machines, refrigerators

Machinery and instrument industry

Glove box, glove box, door panels

Telephones, air-conditioners and other enclosures

Kitchen appliances, recorders,

ABS pipe, ABS sanitary wares, decorative ABS plate

Bar Accessories, tank mask

Computer monitor, typewriter

Auto parts, door linings, ventilation cover

Brackets, buffer capacity expansion board, bumper

Photo: ABS (spray) applications in air conditioning in housing (figure: from Kumho rili)

Photo: ABS (spray) applications in air conditioning in housing (figure: from Kumho rili)

1, ABS, alloys in automotive application

→ Inventory: the auto ABS in family

&Amp;rarr; Audi, VW bus interior door handles selection plating grade PC/ABS why?

Application of 2.ABS in 3D printing

→ Several methods for 3D printing and 3D printing ABS material

3.ABS Mobile Shell applications

&Amp;rarr; application of halogen-free flame retardant PC/ABS in the cell phone case

4.ABS application of purifiers

&Amp;rarr; a free space to breathe (ABS application in air purifiers)

Figure: application of ABS in Purifier housing

Figure: application of ABS in Purifier housing

5.ABS specification

UL-94 flame retardant plastic standard and flame retardant grades for HB, V2, V1 and V0, 5VB, 5VA. Incrementing; ABS according to the use and performance characteristics, can be divided into: General grade level, heat-resistant, level plating, flame retardant, transparent, antistatic, extruded sheet level, pipe and other varieties. More brands, you can click on the blue link:→ under the sky: how rational choice of ABS resin?

Seven, ABS and its alloy of some common problems and solutions

In order for me to let everyone know fuller, so I cannot praise myself, will let people see where I is insufficient. After all, it is a tough man, also has its weaknesses (NBA player LeBron James will cramp) so, I will inevitably produce some problems ( Aging, corrosion and stability ). But, with the awareness of themselves, also found ways to overcome these shortcomings.

1.ABS stress analysis

ABS is amorphous polymers, varying degrees of stress came from the orientation and the hot and cold contraction. Filamentous cracks, cracks includes parts for surface micro-cracking, white, cracked and parts sticky mode, channel stick mold caused by cracks, what these reasons how to solve? Specific methods, you can click on the blue links, viewing:

1) ABS stress crack reason analysis

→ ABS expert tips for you: analysis of stress cracking of ABS

2) PC/ABS analysis of residual stress

&Amp;rarr; teaches you how to analyze residual stress in PC/ABS

3) ABS/PC injection molding problems

Plastic injection molding process, there will always be some problems, here we bring together several common ABS/PC in injection molding process encountered some of the problems and the solutions.

→ PC/ABS injection:” Angel Hair floating fiber defects “ truth revealed!

&Amp;rarr; how to treat PC/ABS injection molding skin in the process?

→ ABS analysis of electroplated four common problems of injection molded parts

&Amp;rarr; how to troubleshoot bad appearance of electroplated PC/ABS parts-design gate

→ [Alloy modification] PC/ABS weld improvement methods

Map: ABS/PC products on the application of weld lines

3.ABS performance issues

Any plastic used in the process would encounter some problems, such as Aging, corrosion, poor stability , the source of these problems, is due to b, butadiene , after polymerization of unsaturated and health ——“ C=C” exists, making it less stable. Here to introduce its causes and some of the methods. Specific details, you can click on the blue links:

1) light aging

→ PC/ABS light aging secrets

2) PVC to ABS of corrosion

&Amp;rarr; dry: corrosion of PVC to ABS do? Experts tell you nonsense!

3) thermal stability of PC/ABS

→ PC/ABS reasons for the poor thermal stability, causing damage and how to upgrade?

Articles by aibang polymer exclusive editing, if reproduced please specify source thanks

Related Industry Knowledge

- Hello, I am a PET, here's my resume! (Collection) manufacturer; manufacturers supply specializing in the modification, processing the custom; modified engineering plastics plastics

- PA/ABS introduction to marriage--enhanced levels; filled plastic; flame retardant; modified processing injection materials nylon PA66; modified nylon and polyamide nylon; modified polyamide engineering plastics

- I am pp, PP called me, here's my resume! Pp; polypropylene fiber modification of polypropylene staple fibre manufacturer plastic

- I'm PE, PE called me, here's my resume! Reinforced grade/flame retardant modified engineering plastics manufacturers

- I am a Pom, POM called me, here's my resume (collection) engineering plastics modification of plastics

- I am a polycarbonate, everyone calls me PC, here's my resume and fill plastic flame retardant

- Car debris box shell mold design analysis (mold industry) enhanced level PA66 + GF30%